PRODUCTS产品中心公司电话:0769-8166 4889 |

产品详情

当前位置:

首页>

产品详情

全国服务热线:0769-81664889

Equipment introduction: The equipment is suitable for docking the customer's assembly line to realize the production of automatic phone sticker accessories; The equipment is designed with an upper carrier structure + a lower tool mechanism to automatically pick up the carrier and automatically put it back on the belt line after the placement is completed, and the reclaiming module can be designed according to the actual line size of different customers; The conveying track of the equipment carrier is a three-stage type to ensure the speed of conveying, and the width of the track is adjustable to improve the versatility of different size carriers; the suction nozzle adopts a quick-release type, which is convenient for fast switching of different products; The machine is equipped with two sets of CCD detection systems up and down to ensure the placement accuracy of accessories; the whole machine is mobile equipment, and is equipped with casters + anti-vibration foot support, which is convenient for moving equipment and ensures the stability and reliability of the machine.

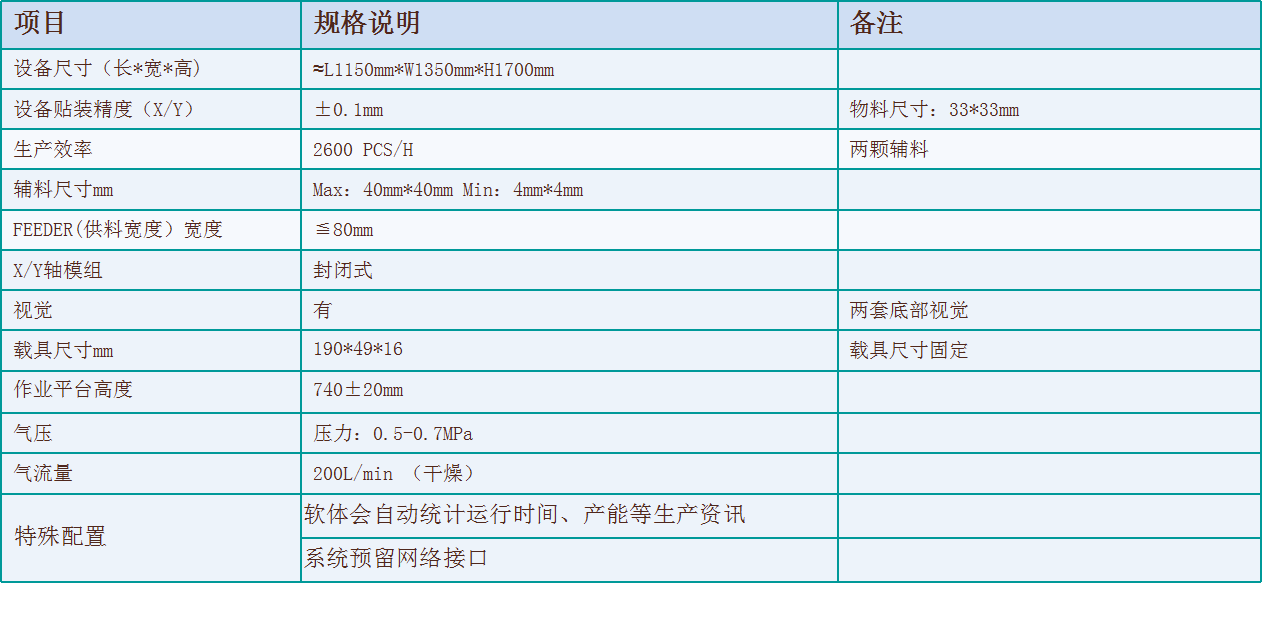

Equipment layout process 1. The carrier is transmitted to the equipment location through the customer transmission line, 2. Manually reclaim the carrier and put it into the track of the auxiliary material machine 3. The carrier flows to the carrier location through the track to locate the carrier 4. The carrier at the positioning position is removed and moved to the auxiliary material station through the equipment sticking mechanism 5. After positioning the carrier product, the product in the carrier is mounted through the attachment mechanism 6. After the placement is completed, the carrier is transferred to the blanking station by the transfer mechanism in the equipment 7. The finished product unloading station manually removes the carrier to the customer's conveyor belt. Technical Parameter

|