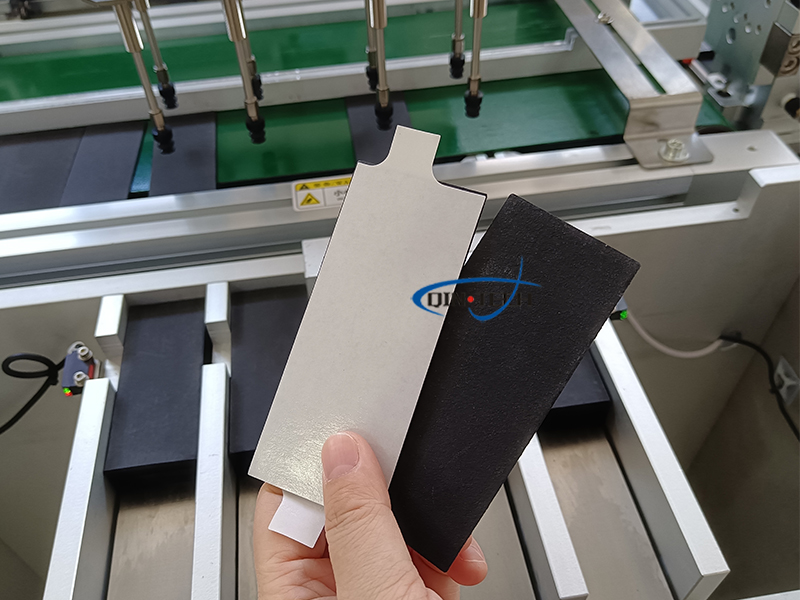

Qin-Tech aerogel heat insulation laminator is an automatic auxiliary material attaching machine independently developed and produced by our company. The equipment can realize the functions of automatic material taking, automatic glue brushing, high precision on the front and back side and automatic feeding. The equipment and products are positioned by mechanical positioning Angle, and the auxiliary materials are CCD visual positioning, which can ensure the installation accuracy of ±0.2mm. The product can be compatible with large size: maximum 220*120mm, minimum 100*45mm.

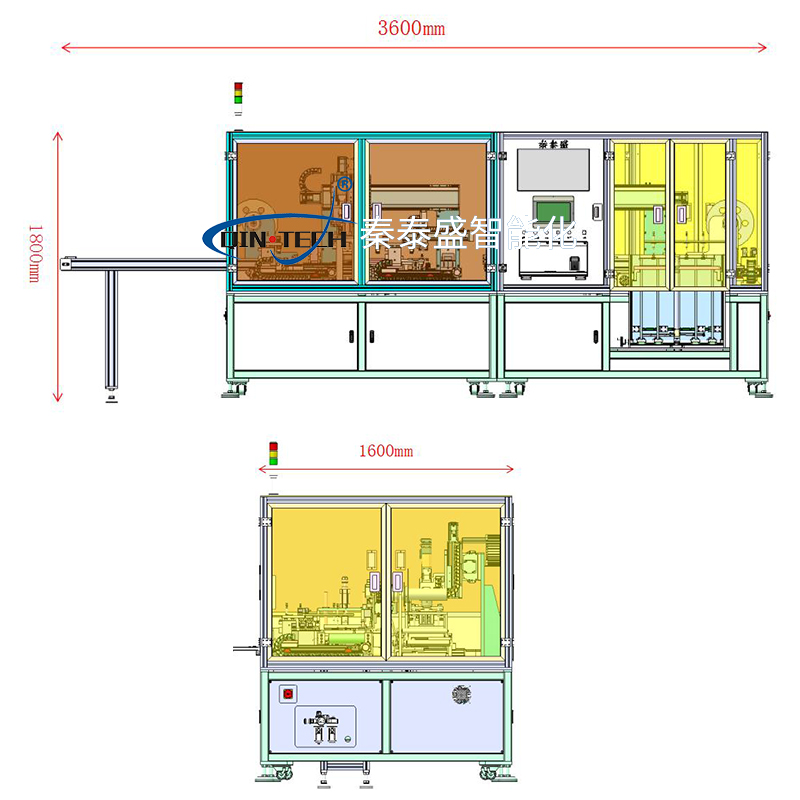

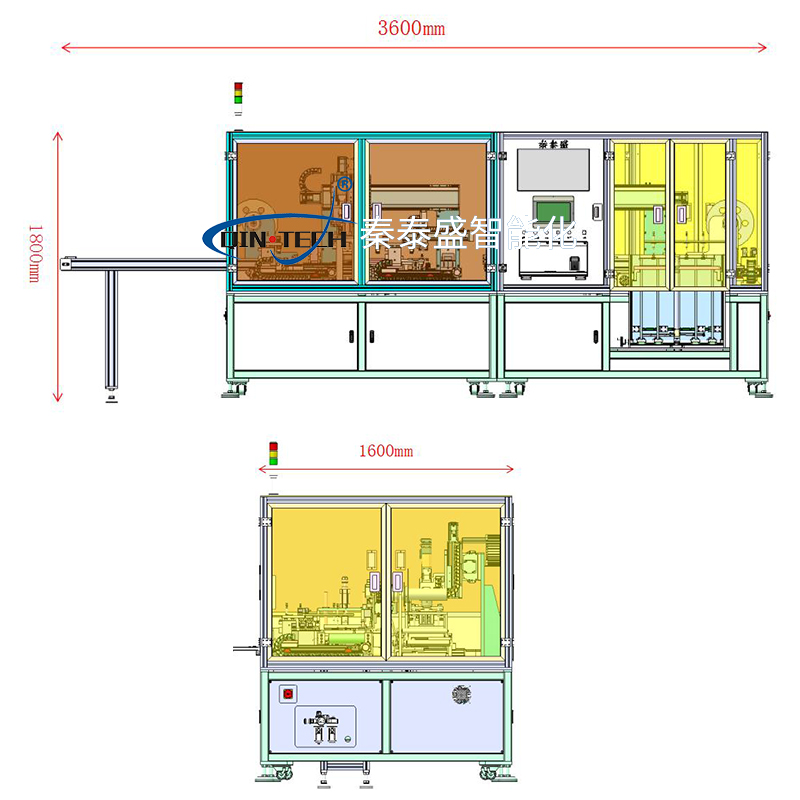

Aerogel insulation sheet laminator overall overview - the whole machine size

1. Height of operation table from ground: 800mm (operating height);

2. Device power: ≈ 5.5Kw;

3. Power supply: 220V 50HZ;

4. Access air source: clean air source 0:4-0.6MPa.

Aerogel insulation sheet laminator Introduction:

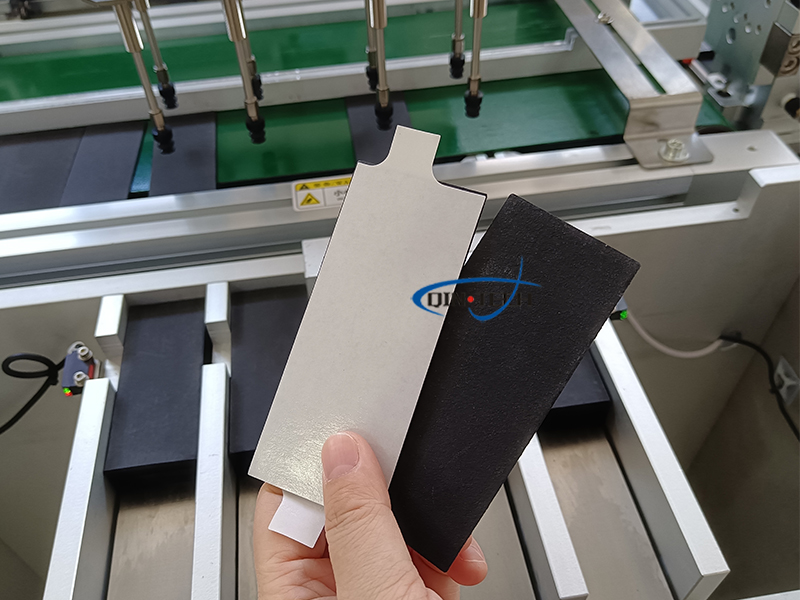

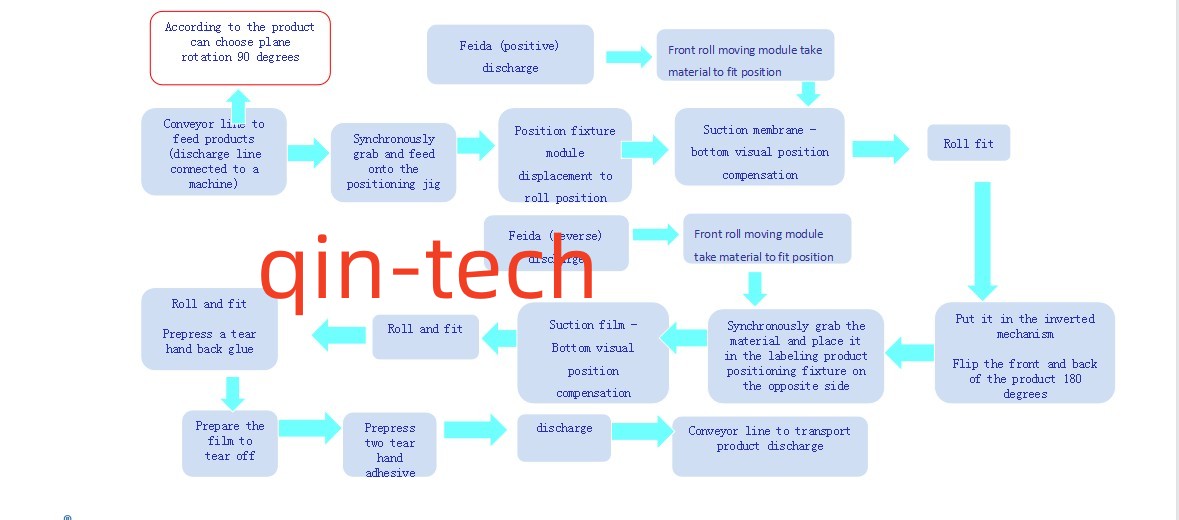

1. Equipment functions: automatic product feeding, automatic brush glue, high precision paste front and back, automatic feeding;

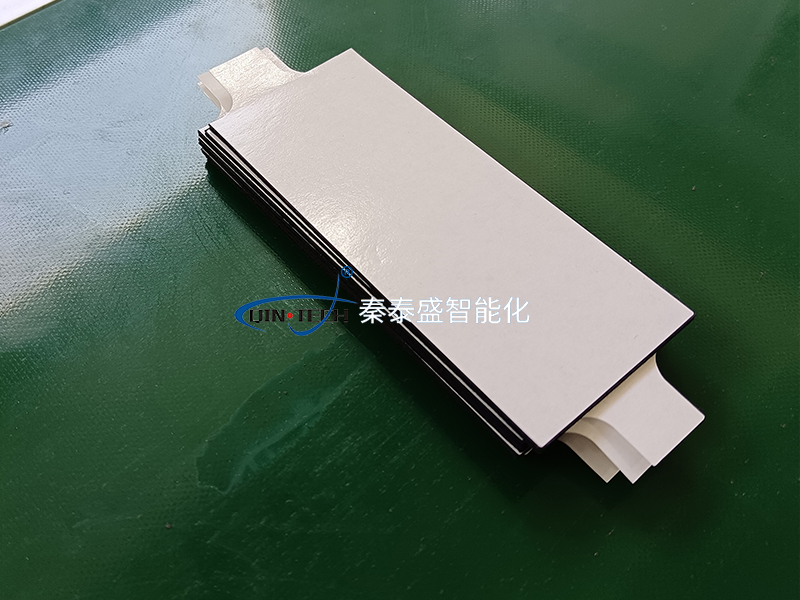

2. Functional process: automatic feeding, product brush glue, stick front double-sided glue, turn over, reverse brush glue, stick back double-sided glue, pressing, automatic feeding;

3. There are four storage positions in the equipment silo, and the capacity height of each silo is 450mm. About 1200PCS of products with a thickness of 1.5mm can be placed at a time;

4. The equipment products use mechanical positioning Angle for positioning, auxiliary materials for CCD visual positioning can ensure the mounting accuracy of ±0.2mm;

5. The product can be compatible with large size: maximum 220*120mm, minimum 100*45mm;

6. The device can select the glue brushing function switch through the software. The glue brushing mechanism can ensure that the amount of glue on the surface of the product is uniform.

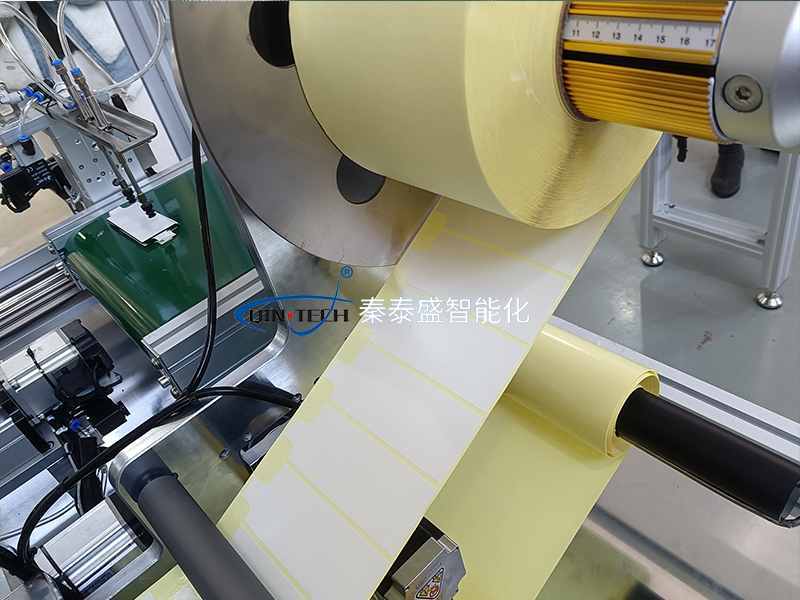

7. When the equipment is pasted with double-sided tape, the rolling paste method can ensure that there are no bubbles between the double-sided tape and the product.

Note: All the online prices of Qin Taisheng are for reference only. Please refer to the actual quotation. Thank you.